Swipe For More >

Stewarding Water Wisely

In arid southwest Kansas, water is not just a resource; it is the lifeblood that sustains agriculture and livelihoods. The precious commodity can make or break a farmer’s success, determining the viability of crops and the future of farming communities.

Brant Peterson, a fifth generation farmer from Johnson, Kansas, understands this better than most. By implementing Dragon-Line, a mobile drip irrigation (MDI) technology, on his farm in this water-stressed region, he decreased water use by 15%—an approach that not only conserves the vital Ogallala Aquifer but also ensures a sustainable future for his land and his family.

The Ogallala Aquifer encompasses 174,000 square miles, supporting one of the most productive agricultural regions in the country. While Peterson already switched many of his acres to less water-intensive crops, like sorghum, converting traditional center pivot irrigation technology to MDI was a strategic investment that is paying off.

“After considering the feasibility of Dragon-Line versus the cost, I ultimately decided to switch because I was convinced that I would be more efficient and save water,” Peterson said. “If those two things proved [to be] true, then the money would take care of itself.”

How MDI Works

Dragon-Line is an innovative MDI system that marries the efficiency of traditional drip irrigation with the flexibility and cost-effectiveness of mechanized systems like center pivots and lateral moves. The system features emitter tubing attached to flexible hosing that drags along the soil surface, delivering water directly to the crop root zone.

Each tube has its own emitter that is pressure compensating and self-flushing, and the length of tubing controls total flow, ensuring the same amount of water is emitted on every inch of the field whether at the tower or at the end of the pivot system. This approach drastically reduces water loss due to evaporation and wind drift while preventing soil compaction, resulting in more efficient water usage.

“On accident, you’re going to see 15% of your savings,” Peterson said. “If you really work at it, you’ll get 20, 25 and even up to 30[%], depending on how efficient you are.”

Reduction in evaporation loss is significant with MDI. A study conducted by Kansas State University in Garden City, Kansas, showed a 35% difference in soil water evaporation before the canopy closes compared to in-canopy spray nozzle systems.

Besides immediate savings in water usage, Peterson is also experiencing more uniform stands and positive yield trends, highlighting the efficiency of his new irrigation system across every acre of the field.

When many farmers across the High Plains struggled with drought conditions during the 2022 growing season, Peterson’s fields told a different story.

“Before I could ask my aerial applicator how a field looked, a text came in saying, ‘before you ask, I want to tell you that is one of the three most uniform fields I’ve flown all year, anywhere,’” Peterson said, shocked at the pilot’s conjecture.

Presenting his success with MDI that year to his local Natural Resources Conservation Service (NRCS), Peterson modestly boasted a 165 bushels per acre corn yield to which the group insisted was a very impressive yield given the drouthy conditions and the fact he was pumping 175 gallons per minute on 62 acres with wheat on the other half of the circle. The 2022 season was also the same year Peterson’s sorghum crop, also under MDI, won top honors in the National Sorghum Yield Contest as the Bin Buster Champion with 245.8 bushels per acre.

Capillary Action

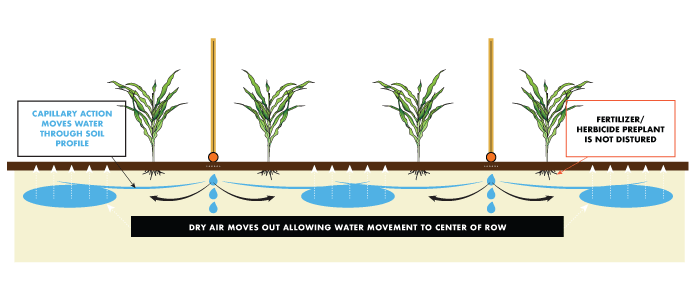

One key finding that demonstrates Dragon-Line’s water-use efficiency compared to conventional irrigation is the way water is allowed to penetrate the soil and move along the subsurface toward the center of the row, displacing dry air. This is known as capillary action.

In a conventional irrigation system, water melts and separates soil in a 3-5 inch depth of application, trapping dry air into the soil, and, until the air moves out, water will not soak in, resulting in sealing and compaction when water is applied.

“My findings show Dragon-Line is 95% as efficient as subsurface drip,” Peterson said. “The capillary action is what makes this work that well.”

Subsurface moisture is more uniform on Peterson’s fields using Dragon-Line, a notable change from patches that were once dry, hard or underperforming.

“Each agronomist has told me when they go to probe the field in the spring for pre-water, that it’s the most uniform field they probe,” he said.

Other benefits Peterson sees with Dragon-Line include elimination of wheel line issues, applied nutrients stay with the plant instead of leaching and keeping foliar dry reduces insect and disease pressure.

There are challenges. Peterson said his most common issue is a build up of iron bacteria that is in the water, which can collect in the emitters in the drip line, reducing flow. He manages this issue with a small, slow chlorine pump to kill the bacteria.

“If you try to manage it from the road like you do your sprinklers, you cannot assume your pressure is good and your gallons are right,” he said, “because you cannot see it or see that the nozzles are not plugged. It’s different.”

An Ambassador for the Technology

The success Peterson is experiencing with Dragon-Line has turned him into an ambassador for the technology, recently completing a trip to Egypt where he met with a 26,000-acre irrigated farm to help properly calibrate their technology, report findings from his farm and field questions. Dragon-Line, invented in Ulysses, Kansas, is now being used in more than 22 states and 20 countries.

At the end of June, Peterson was featured on PBS NewsHour, a nightly hour-long television broadcast that shed light on the dwindling Ogallala Aquifer and steps area producers are taking to mitigate its decline. In addition to highlighting efforts to plant less water thirsty crops like sorghum, he also shed light on irrigation efficiency and good stewardship.

At $250-$350 per acre, depending on system needs for filtration and other options, and the ability to withstand 10-12 years of wear, the MDI system has been a worthwhile investment for Peterson and his bottom line—and he has plans for expansion. Peterson also emphasized the importance of thinking about downstream markets and consumer demand.

“How can I capitalize on this?” he asks, highlighting the growing consumer interest in sustainably grown products that reduce water use. By adopting MDI technology, Peterson is not only conserving water and enhancing his farm’s productivity but also positioning himself to meet the increasing demand for environmentally friendly agricultural practices—a forward-thinking approach that ensures his farm remains competitive and sustainable for future generations.

###

This story originally appeared in the Summer 2024 Issue of Sorghum Grower magazine.